In industries where strength, lightweight performance, and durability are essential, aluminum honeycomb sandwich panels have emerged as one of the most efficient materials available. Their unique construction delivers exceptional rigidity while keeping weight to a minimum, making them ideal for applications in transportation, construction, and industrial manufacturing.

Composite Box provides high-quality aluminum honeycomb sandwich panels designed to meet the strictest industry requirements, ensuring reliability, performance, and longevity in every project.

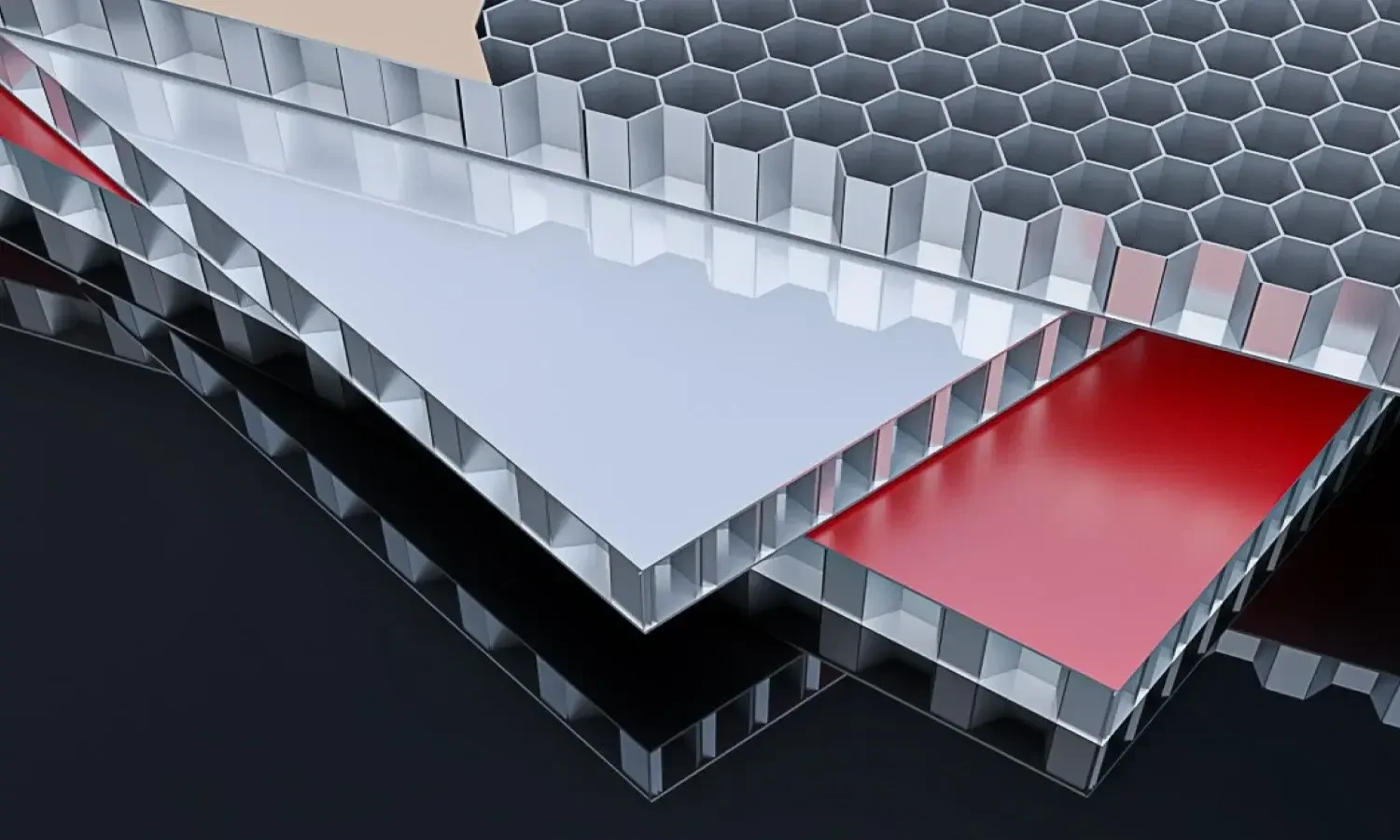

What Are Aluminum Honeycomb Sandwich Panels?

Aluminum honeycomb sandwich panels are engineered composite materials that consist of two thin aluminum sheets bonded to a lightweight honeycomb core. The honeycomb structure provides excellent strength-to-weight ratio while offering high resistance to compression and bending.

Key Advantages:

- Lightweight Design: Significantly lighter than solid metal sheets, reducing overall structure weight.

- High Strength: Exceptional stiffness and durability without adding unnecessary mass.

- Corrosion Resistance: Aluminum naturally resists rust and environmental damage.

- Thermal and Acoustic Insulation: The honeycomb core helps regulate temperature and dampen noise.

Why Industries Choose Aluminum Honeycomb Sandwich Panels

The versatility of aluminum honeycomb sandwich panels makes them suitable for a wide variety of uses:

1. Transportation Industry

In trucks, ships, trains, and aircraft, weight reduction is crucial for fuel efficiency. These panels offer structural stability while keeping vehicles lightweight, improving performance and lowering operational costs.

2. Construction and Architecture

From building facades to interior partitions, aluminum honeycomb panels provide an attractive, durable, and fire-resistant solution. Their sleek finish and ability to withstand environmental stress make them ideal for long-term installations.

3. Industrial Applications

Machinery platforms, cleanroom walls, and workstations often require strong yet lightweight materials. These panels provide a perfect balance of functionality and ease of installation.

The Composite Box Quality Advantage

When sourcing aluminum honeycomb sandwich panels, quality manufacturing is critical. Composite Box is known for delivering panels that meet or exceed performance expectations.

Precision Engineering

Every panel is manufactured using advanced bonding technology to ensure consistent strength and structural integrity.

Premium Materials

Only high-grade aluminum is used for both the skins and honeycomb core, ensuring superior corrosion resistance and durability.

Custom Sizing and Finishes

Composite Box offers tailored panel dimensions, thickness options, and surface finishes to meet specific client needs.

Strict Quality Control

Each batch undergoes rigorous testing to ensure uniformity, strength, and adherence to safety standards.

Benefits Over Traditional Materials

Choosing aluminum honeycomb sandwich panels provides clear advantages over solid metals or other composites:

- Weight Savings: Ideal for projects where weight reduction translates to performance gains or easier handling.

- Structural Efficiency: High rigidity allows for thinner panels without compromising strength.

- Design Flexibility: Panels can be shaped, cut, and finished to match various project requirements.

- Sustainability: Aluminum is recyclable, making these panels an eco-friendly option.

Common Applications

Aerospace and Marine: Lightweight panels help reduce fuel costs and improve performance.

Automotive: Used in body panels, floors, and partitions for commercial vehicles.

Architecture: Decorative walls, ceilings, and cladding that combine style with strength.

Industrial Equipment: Platforms, tool stations, and enclosures that require rigidity and portability.

Factors to Consider When Selecting Panels

When choosing aluminum honeycomb sandwich panels, important factors include:

- Load Requirements: Ensure the panel thickness and core density match the intended structural needs.

- Environmental Exposure: Consider coatings or finishes for additional weather resistance.

- Thermal Needs: Panels can be designed for insulation or heat dissipation depending on the application.

- Installation Method: Custom sizing and pre-drilled options can simplify on-site assembly.

Conclusion

Aluminum honeycomb sandwich panels from Composite Box deliver unmatched strength-to-weight performance, making them a top choice across multiple industries. Their durability, customization potential, and efficiency make them ideal for demanding applications in transportation, construction, and industrial manufacturing.

By investing in high-quality panels from a trusted supplier, businesses can ensure long-term performance, improved efficiency, and reliable structural solutions that stand the test of time.